The dispersibility of the pigment is directly related to the fineness, gloss and other important quality indicators, and it can shorten the grinding time. Although pigment production plant can be produced with easy dispersing type pigments, but the existence of some varieties of pigment difficult to disperse. The customer needs in accordance with different resin systems to select wetting and dispersing agent, to get better color development, hiding power and storage stability.

Wetting & Dispersing Agent

The advantages of using wetting agent and dispersing agent:

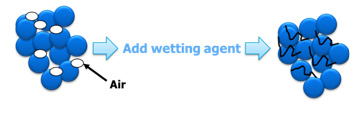

Removal of adsorbed air from the pigment surface; subsequent formation of pigment/resin interface.

It needs to control the viscosity of coating and contact angle.

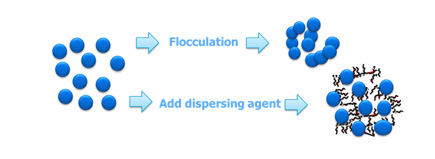

Mechanical dispersing of all pigment agglomerates which may be present (Provision of rather a 100% primary particle state or controlled flocculation state)

It is to control the grinding time, grinding temperature and particle distribution of pigment.

Hindrance of reversion to a reagglomerated or uncontrolled Flocculation state.

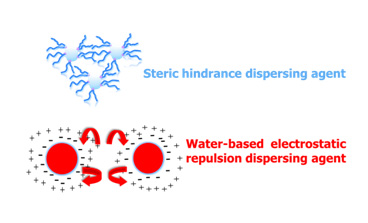

The most important is that building of force field of varying natures (Including electrostatic/steric/physical/chemical) around either the idealized primary particle or the controlled flocculation entity.

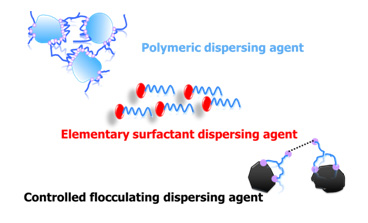

The kind of wetting agent and dispersing agent:

Wetting and Dispersing Agent

Product ID | Composition | Application | Dosage |

Ritzad DP-1 | Phosphoric ether | Be suited for aqueous and non-aqueous systems. To improve color development for organic pigment or difficult disperse pigment. It can reduce the grinding time and mill-base viscosity. To enhance gloss, color development and transparency of film. | 0.5 - 3% based on total pigment |

Ritzad DP-2 | Solution of salt polyamide and polyester, electroneutral | It is highly effective wetting and dispersing agent to improve the wetting of pigment surface, wood surface and organically treated Bentonites. Good wetting performance to improve the wetting of filler surface and pigment surface, it assists foam-releasing to save the grinding time. | 10 - 50% based on total organic bentonite / 0.3 - 5% based on total inorganic pigment / Wood Primer: 0.5 - 2% based on total fillers |

Ritzad DP-3SL | Solution of polycarboxylic acid polymer with a polysiloxane copolymer | Highly effective in preventing floating and flooding of the most of color paste system. It is a very effective flow promoter and eliminates surface disturbances in the film when added at the proper level. In addition, the scratch resistance and slip properties of the film are considerably improved. | 2 - 5% based on total organic pigment / 0.5 - 3% based on total inorganic pigment |

Ritzad DP-4 | Solution of a copolymer with acidic groups | It is special designed to disperse inorganic pigment or fillers especially for TiO2, Talc and CaCo3.To produce higher than 75% pigment loading (TiO2) color paste. It prevents reflocculation of pigment. No effect on the weather resistance. | 2 - 8% based on total organic pigment / 0.5 - 5% based on total inorganic pigment / 0.5 – 3% based on total filler amount |

Ritzad DP-5 | Polyurethane compound | Good dispersing effect and heat storage stability of pigment concentrations. It is suitable for organic pigment in solvent-based coating system, exhibit good wetting and dispersing performance. Recommended in low to medium polarity systems. It prevents reflocculation of pigment through strict hindrance and reduces the time required for the grinding process. | 40 - 120% based on total organic pigment / 0.5 - 5% based on total inorganic pigment |

Ritzad DP-7W | Alkyl polyethleneoxide ether | Excellent wetting and dispersing performance to enhance incorporation of hydrophobic pigment into emulsion paint or aqueous coatings. To improve the color acceptance. Suitable to use for universal color paste system. Good compatibility, so it can be added at in any stage. | 0.1 - 2% based on total pigment |

Ritzad DP-8 | High molecular weight polymer | It is characterized by its multi-pigment-affinic groups, strong adsorption and thick barrier, especially in preventing dispersed pigments from re-flocculation. And excellent wetting and dispersing performance for carbon black pigment in medium polar system, good dispersing effect and heat storage stability of pigment concentrations. It is suitable for organic pigment in solvent-based coating system. | 20 - 80% based on total organic pigment / 0.5 - 5% based on total inorganic pigment |

Ritzad DP-9 | Anionic surfactant | It is a unique wetting and dispersing agent as well as grinding vehicle specially designed for carbon black pigment especially in alkyd resin system. It can add to the mill-base, also as grinding vehicle to prepare pigment pastes for tinting or colouring. It is also suitable to disperse Prussian blues, transparent iron oxides. | 20 - 80% based on total organic pigment |

Ritzad DP-2115 | Surface active compound | It is a highly concentrated liquid pigment dispersing agent for application in organic solvent-borne systems. It has excellent dispersing effect for inorganic and organic pigments. To improved compatibility of universal colorants. Recommended in low to medium polarity systems. | 40 - 60% based on total organic pigment / 2 - 5% based on total inorganic pigment / In alkyd resin system, 0.2 - 1% based on total formulation |

Ritzad DP-2422 | Modified polysiloxane | It is an anti-floating, anti-flooding additive for solvent based paints. Post-added as a correction aid in color matching to minimize color non-uniformity. Also can use it with grinding stage. To enhance surface leveling, flow and gloss. | 0.1 - 1% based on total formulation. |

Ritzad DP-2512W | Sodium salt of a polyacrylic acid | It is an aqueous dispersing agent which has good pigment dispersing and stabilizing the pigment used in emulsion paint or aqueous coatings. Low odor and it can maintain the viscosity and stability of emulsion paint. | 4 - 10% based on total organic pigment / 1 - 3% based on total inorganic pigment |