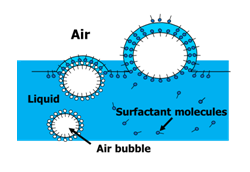

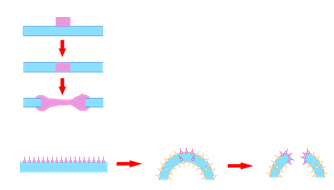

Defoamers will change the surface tension on foam to destroy the foam from coating film. Normally, silicone type defoamer has low surface tension that will be easier to absorb on bubble surface, it effects the bubble surface becomes imbalance, and then bubble will destroy immediately. We also produce non-silicone type defoamer which is based on the incompatibility to destroy the foam, it has better anti-foaming and air-releasing performance when compared to silicone type defoamer, especially non-silicone type defoamer doesn’t effect to recoatability.

Defoamer, Anti-foaming & Air-releasing Agent

Product | Composition | Application | Dosage |

Ridfom SDK-1 | Modified polysiloxane | It has good defoaming efficiency for 2K PU. Easily release CO2 during reaction of polyurethane. | 0.2 - 2% based on total formulation |

Ridfom SDK-2 | Polysiloxane containing hydrophobic particles | Excellent bubble releasing and anti-foaming agent for solvent and solvent-free systems. It is suitable for epoxy flooring, printing ink, UV ink, PCB ink, unsaturated polyester and UV curing coatings. | 0.01 - 1% based on total formulation |

Ridfom SDK-3 | Modified polysiloxane | Excellent anti-foaming and defoaming properties to prevent foaming of solvent based systems caused by mechanical force such as mixing, production and application. Especially for wood primer and UV coating. | 0.2 - 1% based on total formulation |

Ridfom SDK-4AF | Modified polysiloxane | Aromatic solvent free defoamer which has excellent anti-foaming and defoaming properties to prevent foaming of solvent based systems caused by mechanical force such as mixing, production and application. Easily release CO2 during reaction of polyurethane. | 0.2 - 1% based on total formulation |

Ridfom SDK-5W | Modified polysiloxane | It is a long-lasting anti-foaming and defoaming agent which can dilute with water directly. Good compatibility and good defoaming efficiency for aqueous coatings. It is recommended to be added into mill-base, the rest during the let-down process. | 0.01 - 1% based on total formulation |

Ridfom SDK-6 | Modified polysiloxane | It is a bubble releasing, anti-foaming agent for solvent-based coatings and leather industry. | 0.2 - 2% based on total formulation |

Ridfom SDK-7AF | Modified polysiloxane | Aromatic solvent free defoamer which has excellent anti-foaming and defoaming properties to prevent foaming of solvent based systems caused by mechanical force such as mixing, production and application. Easily release CO2 during reaction of polyurethane. | 0.2 - 1% based on total formulation |

Ridfom SDK-4110W | Polysiloxane emulsion | It is APEO-free, long-lasting, anti-foaming and defoaming agent which can dilute with water directly. Good compatibility, no effects on gloss and transparency. Recommended to be added into mill-base, the rest during the let-down process. Please reduce the dosage when film surface shows pin-hole. | 0.2 - 1% based on total formulation |

Ridfom SDK-4211 | Polysiloxane containing hydrophobic particles | Excellent bubble releasing and anti-foaming agent for solvent and solvent-free systems. It is suitable for solvent and solvent-free system, included epoxy flooring, printing ink, UV ink, PCB ink, unsaturated polyester and UV curing coatings. It has excellent air releasing efficiency in high viscosity and film thickness system. Good stability in storage, no separation. | 0.01 - 1% based on total formulation |

Ridfom ADK-1 | Foam destroying polymer | Silicone-free bubble releasing and anti-foaming agent for solvent and solvent-free systems. It will be most suitable for high viscosity system, such as epoxy, unsaturated polyester and UV curing coatings. | 0.1 - 2% based on total formulation |

Ridfom ADK-2 | Foam destroying polymer | Silicone-free bubble releasing and anti-foaming agent for solvent and solvent-free systems. It will be most suitable for high filler content system, such as wood primer containing zinc stearate or stoving paint system. | 0.1 - 0.5% based on total formulation |

Ridfom ADK-4399 | Foam destroying polymer | Solvent-free and silicone-free type defoamer for solvent and solvent-free systems. It has good anti-foaming and defoaming efficiency, it also can improve the leveling on the coating surface. | 0.1 - 0.5% based on total formulation |

Ridfom MS-47W | Mixture of mineral oil and hydrophobic particle | Special mixed aqueous defoamer, excellent water dispersion. It is very suitable for sensitive paint system. APEO-free, good compatibility with most resins system. | 0.2 - 0.5% based on total formulation |

Factors Effect Formation of Foam:

- Poor substrate wetting

- High viscosity

- Too fast drying

- High humidity

- High shear rate during application

- High water content of raw material

- Contain surfactant or other materials

The requirements of defoamer:

- lower surface tension than other ingredients

- incompatibility or lightly compatibility

- high efficient expanding speed

- easily handle

- be inert

- no side effect